Shaw Versalock Vinyl Plank Information

Click here to download this information guide, and click here to browse our Shaw Products.

INSTALLATION GUIDELINES FOR VERSALOCK® VINYL PLANK

I. GENERAL INFORMATION

These installation guidelines apply to the VersaLock® product only. All instructions and recommendations should be followed for a satisfactory installation.

- The floor covering should be stored and installed in a climate controlled location with an average temperature between 65° - 85°F - 18°- 29°C.

- Acclimate material 48 hours prior to installation in the room/ location where the installation will take place.

- Do not store directly on concrete, allow for air circulation. Do not open the cartons but spread them out and protect corners from damage.

- Failure to follow these guidelines may result in an installation failure (i.e. flooring may expand or contract, resulting in gapping). VersaLock® Plank is an interior product and must be installed in a temperature- controlled environment, maintained between 65 and 85 degrees F - 18°-29°C. Please keep in mind a concrete floor can be up to ten degrees colder than the actual room temperature.

- Avoid exposure to direct sunlight for prolonged periods, doing so may result in discoloration. During peak sunlight hours, the use of the drapes or blinds is recommended.

- Regardless of new construction or remodeling projects, keep flooring stored in rooms that are not being worked in and only install product after all other trades have completed work that could damage the flooring.

- To minimize shade variation, mix and install planks from several cartons.

- Inspect all planks for damage before installing. If you have any concerns about the product fit or finish, call Shaw Information Services at 800-441-7429. Claims will not be accepted for flooring that has been cut to size and/or installed.

- Use cementitious patching and leveling compounds that meet or exceed Shaw’s maximum moisture level and pH requirements. Use of gypsum-based patching and/or leveling compounds which contain Portland or high alumina cement and meet or exceed the compressive strength of 3,000 psi are acceptable.

- Installation – This product can be installed on, above, or below grade.

- VersaLock, Shaw’s patented locking technology, is water/moisture resistant and reliably secures the flooring panels on all four sides. However, excessive moisture in the subfloor could promote mold, mildew, and other moisture related issues like the trapping of moisture emissions under the flooring, which may contribute to an unhealthy indoor environment.

- Shaw Industries does not warrant nor is responsible for damage to floor covering due to moisture related issues.

Tools: Tape Measure, Utility Knife, Tapping Block, Pull Bar, ¼" Spacers, T-Square, Safety Glasses, Broom or Vacuum and, if necessary, tools for subfloor repair.

II. SUBFLOOR INFORMATION

All subfloors must be clean, flat, dry and structurally sound. The correct preparation of the subfloor is a major part of a successful installation. Roughness or unevenness of the subfloor may telegraph through the new floor covering, resulting in an unsightly surface and may cause excessive wear on high spots. Subfloor must be flat – 3/16" in 10' or 1/8" in 6'.

CAUTION: Some types of nails, such as common steel nails, may cause discoloration of the vinyl floor covering. Recommendations for attaching underlayment panels are not included. Solvent based construction adhesives are known to stain vinyl floor coverings. All responsibility for discoloration problems caused by the use of the above mentioned products is not the responsibility of Shaw, but rests with the installer and the underlayment panel manufacture.

A. Wood Subfloors

- Do not install material over wood subfloors that lay directly on concrete or over dimensional lumber or plywood used over concrete.

- Do not apply sheet plastic over wood subfloors.

- Basements and crawl spaces must be dry. Use of a 6 mil black polyethylene is required to cover 100% of the crawl space earth. Crawl space clearance from ground to underside of joist is to be no less than 18” and perimeter vent spacing should be equal to 1.5% of the total square footage of the crawl space area to provide cross ventilation. Where necessary, local regulations prevail.

- DO NOT install over sleeper construction subfloors or wood subfloors applied directly over concrete.

- All other subfloors - Plywood, OSB, particleboard, chipboard, wafer board, etc. must be structurally sound and must be installed following their manufacturer’s recommendations. Local building codes may only establish minimum requirements of the flooring system and may not provide adequate rigidity and support for proper installation and performance.

- If the surface of the wood subfloor is not smooth, a 1/4" underlayment panel must be installed over the subfloor, per the underlayment manufacturer’s written instructions.

- Versalock resilient flooring is not recommended directly over fire-retardant treated plywood or preservative treated plywood. An additional layer of APA rated 1/4" thick underlayment should be installed.

- Crumb rubber underlayments are not an acceptable option for use with resilient floor coverings due to performance issues resulting from chemical incompatibilities.

B. Concrete Subfloors

- New and existing concrete subfloors should meet the guidelines of the latest edition of ASTM F 710, “Standard Practice for Preparing Concrete Floors to Receive Resilient Flooring” available from the American Society for Testing and Materials, 100 Barr Harbor Drive, West Conshohocken, PA 19428; 610-832-9585; http://www.astm.org

- Floors shall be smooth, permanently dry, clean, and free all foreign material such as dust, wax, solvents, paint, grease, oils, and old adhesive residue. The surface must be hard and dense, and free from powder or flaking.

- If the adhesive residue is asphalt‐based (cut‐back), or any other type of adhesive is present, it must be removed by industry accepted methods such as mechanical removal or wet scraping.

- If a chemical abatement has been performed, use Shaw Surface Prep EXT to remove any residual chemicals present. Once Shaw Surface Prep EXT has been properly cleaned and removed, apply one coat of Shaw MRP for additional protection.

- Adhesive removal through the use of solvents or citrus adhesive removers is not recommended. Solvent residue left in or on the subfloor may affect the new adhesive and floor covering.

These products may contain either asbestos fibers and/or crystalline silica. Avoid creating dust. Inhalation of such dust is a cancer and respiratory tract hazard. Smoking by individuals exposed to asbestos fibers greatly increases the risk of serious bodily harm. Unless positively certain that the product is a non‐asbestos‐containing material, you must presume it contains asbestos. Regulations may require that the material be tested to determine asbestos content and may govern the removal and disposal of material. See current edition of the Resilient Floor Covering Institute (RFCI) publication Recommended Work Practices for Removal of Resilient Floor Coverings for detailed information and instructions on removing all resilient covering structures. For current information go to www.rfci.com.

- New concrete slabs must be dry. Maximum moisture level per CaCl test method is 8 lbs. per 1000 in 24 hr. Maximum level for ASTM 2170 In-situ Relative humidity test method - 85%.

- Do no install over concrete with a history of high moisture or hydrostatic conditions.

- Maximum acceptable ph level of 10 or less

- The final responsibility for determining if the concrete is dry enough for installation of the flooring lies with the floor covering installer.

- Holes, grooves, expansion joints and other depressions must be filled with a Portland based patching and levelling product, and troweled smooth and feathered even with the surrounding surface.

Radiant Heating: Radiant-heated subfloor systems can be concrete, wood or a combination of both.

The heating systems components must have a minimum of 1/2" separation from the flooring product. The system must be on and operational for at least 2 weeks prior to installation to reduce residual moisture. Three days prior to installation lower the temperature to 65 degrees, after installation gradually increase the temperature in increments of 5° F to avoid overheating. Maximum operating temperature should never exceed 85°F. Use of an in-floor temperature sensor is recommended to avoid overheating. Contact the manufacturer of your radiant heating system for further recommendations.

- Electric Radiant Floors: consist of electric cables (or) mats of electrically conductive materials mounted on the subfloor below the floor covering. Mesh systems are typically embedded in thin-set. When embedding the system components, use cementitious patching and leveling compounds that meet or exceed Shaw’s maximum moisture level and pH requirements. Use of gypsum-based patching and/or leveling compounds which contain Portland or high alumina cement and meet or exceed the compressive strength of 3,000 psi are acceptable.

- Hydronic Radiant Floors: pump heated water from a boiler through tubing laid in a pattern under the flooring. Typically installed in channels under a wooden subfloor (or) imbedded in concrete slabs. Requires the installer follow a specific nailing pattern to avoid penetration of the heat system.

C. EXISTING FLOOR COVERINGS

- VersaLock flooring can be installed over most existing hard–surface floor coverings, provided that the existing floor surface is clean, flat dry and structurally sound.

- Quarry tile, terrazzo and ceramic tile - Use caution with highly embossed tile. This type of tile plus grout joints should be filled with a high quality cementitious patching product.

- When the removal of the existing resilient floor covering is not an option then it must be covered with an embossing levelling compound or an equivalent in order to provide a smooth subfloor surface. Otherwise, telegraphing may occur.

- Existing sheet vinyl floors should not be heavily cushioned and not exceed more than one layer in thickness. Soft underlayment and soft substrates will diminish VersaLock's inherent strength in resisting indentations.

- Installation is NOT allowed over any type of carpet.

III. INSTALLATION

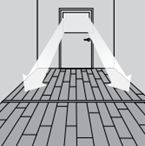

VersaLock plank flooring is designed to be installed utilizing the floating method only. Never secure the planks to the subfloor. Do not install cabinets or fixed objects on top of the flooring. Proper expansion space is required. Undercut all doorjambs. Do not fasten wall mouldings and or transition strips to the planks.

|

|

|

|

- Before you start with the installation, it is important to determine the layout of the flooring. Proper planning and layout will prevent having narrow plank widths at wall junctures or very short length pieces at the end of rows.

- As with all plank products, install the planks parallel to the longest exterior wall.

- Determine if the starter row will need to be cut. If the first row of planks does not need to be trimmed in width, it will be necessary to cut off the unsupported tongue so that a clean, solid edge shows towards the wall.

- Installation of the product must start from the left side of the room, working to the right when working in front of the planks or facing the starting wall.

- Install the second plank in the row by angling the end tongue into the end groove of the first plank. Be careful not to bend the corner of the plank. Maintain an expansion gap of approximately 5/16" - 8mm from the wall. Start the second row by cutting a plank to the desired length. Keep in mind that the plank must not be shorter than 6" (15cm) to achieve the best appearance.

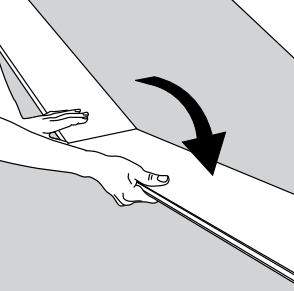

- Install the first plank in the second row by inserting the long side tongue into the groove of the plank in the first row. This is best done with a low angle of the plank. Maintain pressure into the side seam as you rotate the plank to the subfloor. Install the second plank in the second row by inserting the short end tongue into the previously installed plank groove. Align the plank so that the long side tongue tip is positioned just over the groove lip of the plank in the first row. Working from the end seam, at a low angle, insert the long tongue into the groove of the adjoining plank. Very little force is required to seat the tongue into the groove. You should feel the tongue lock into the groove.

- Work across the length of the room installing planks along the wall in the first row and then aligning the planks in the second row. It is critical to keep these two rows straight and square, as they are the “foundation” for the rest of the installation. Check squareness and straightness often.

- Cut the last plank in the first row and leave an expansion gap of around 5/16" - 8mm. Planks may be cut with a utility knife using the “score and snap” technique. The leftover of this plank may be used to start the third row if it’s a minimum 6" - 15cm long.

- Continue installing planks and make sure to achieve a random appearance with end pieces of minimum 6" - 15cm. Check that all planks are fully engaged; if a slight gapping is found, the gap can be tapped together by using a tapping block and a scrap of flooring to cover the tapping block in order to avoid damages on the planks.

- When fitting under door casings, etc., the flexibility and convenient connection of VersaLock becomes evident. If necessary, a flat pull bar may be used to assist in locking the planks.

- When fitting around obstacles or into irregular spaces, planks can be cut easily and cleanly using a utility knife with a sharp blade. It is often beneficial to make a cardboard template of the area and transfer this pattern to the plank.

- Protect all exposed edges of the flooring by installing wall moulding and/or transition strips. Make sure that no plank will be secured in any way to the sub floor.

- For wet areas such as bathrooms caulk the perimeter of the floor with a silicone caulk.

- Protect the finished flooring from exposure to direct sunlight to reduce fading and thermal expansion.

- Do not use tape to secure floor protection during construction or renovation. Use ram board or similar to protect the floor.

IV. REPAIRS

- VersaLock plank flooring is tough and durable; however, if a plank becomes damaged, it can be replaced. If the damaged plank is along the perimeter of the room, the easiest technique is to disconnect the planks until the damaged plank is removed. Replace the plank and reassemble the planks. If it is impractical to disconnect and reassemble the flooring, the following procedure should be followed:

- It’s recommended to use painters tape along the sides of the board to be replaced to prevent damage to the adjoining boards.

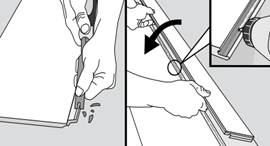

- Using a Utility Knife, cut through the center of the damaged plank, running the length of the plank.

- Carefully remove cut pieces from the insert. You can use a utility knife to remove the pieces from the floor. Clean up any debris from opening area.

- To prepare replacement plank. Cut and remove tongue from the long side and the short end of the plank. This can be accomplished by using a Utility knife.

- Using a Utility Knife, remove approximately 1.5 inches of the groove on the long side of the plank from the tongue end.

- Apply a small bead of super glue (Ethyl Cyanoacrylate adhesive) to the groove of the boards in the floor.

- Insert replacement plank, locking the long side joint (groove side) into the existing floor. NOTE: The tongue end of the replacement plank will overlap the existing floor prior to be fully inserted.

- Using a scrap piece of plank as a tapping device, tap the groove end into place. Insert the blade of a Utility knife on the opposite side to lift and adjust the end as it is being tapped into place.

- Place a weight on the plank until the adhesive sets. (Shaw recommends minimum 6-8 hours).

|