Axiscor Performance Pro LVP And Vinyl Installation Guides

Click here to download this guide as a PDF, and click here to browse our Axiscor Performance products.

AXISCOR LUXURY RIGID CORE SPC FLOORING

Inspect ALL materials carefully BEFORE installation. Warranties DO NOT cover materials with visible defects once they are installed.

It is the responsibility of the installer/owner to determine if the job site subfloor and job site conditions are environmentally and structurally acceptable for Axiscor floor installation. The flooring manufacturer declines any responsibility for Axiscor floor failure resulting from or connected with subfloor, subsurface, job site damage or deficiencies after flooring has been installed.

CHECKLIST:

- Flooring should only be installed in temperature-controlled environments. It is necessary to maintain a constant temperature 48 Hours before, during and after the installation.

- Store the packages in the future room climate and open package after package

- This floor will be floating installed, i.e. always keep a minimum 1/4” distance to all walls and vertical obstructions. Do not install cabinets on top of this product

- Check your subfloor, it must be dry (measure always!), clean, firm, and flat.

- Measure the room and decide installation direction. Note the limitations as per below

- Transition are required only if installing AXISCOR in a room or area that is larger than 100 lineal ft. in any direction.

- Radiant Heat – see IN-FLOOR RADIANT HEAT and requirements below.

- Check your floor continuously during the installation. Defective boards that are installed are not covered by warranty.

- To preserve your floor, clean and maintain your floor correctly.

Tools for Installation:

- Utility Knife

- ¼" Spacers

- Soft-Faced Rubber Mallet

- Straight Edge

- Pencils

- Broom

- Measuring Tape

- Eye Protection

- Felt Pads

Optional: Jig Saw, Table Saw, Miter Saw, Circular Saw, Hole Saw, Moisture Meter (wood, concrete, or both). Power tools can be dangerous, operate in strict accordance with manufacturer’s operating instructions and safety precautions.

GENERAL REQUIREMENTS (ALL SUBFLOORS)

- Must be flat to within 3/16” in a 10ft span; no bumps or low spots. Subfloors should not slope more than 1" per 6ft

- Must be clean: no construction debris, soil, mud or any other objects on or adhering to the floor. I f necessary, scrape and sweep away before the installation; no protrusions of nails, debris, or metals should remain.

- Must be free from moisture-related conditions that can damage the installed flooring.

- Be structurally sound without deflection.

Important Information:

- You should allow for 5%-10% more flooring than square footage to account for cuttings and waste

- When installing the subfloor flatness tolerances should be no more than 3/16” in 10 ft. Radius and there should be no abrupt height differences. High spots should be sanded or ground down and low areas should be filled.

- Over concrete subfloors we recommend using 6 mil polyfilm moisture barrier.

- If excessive moisture, over 85% RH, is present or if slab moisture cannot be verified, the use of a 6 mil polyfilm moisture barrier is required. The moisture barrier should be overlapped six inches and taped at the seams.

- AXISCOR includes a pre-attached sound reduction pad therefore no underlayment is required.

- Do not use any additional sound suppression underlayment or padding, as doing so will void the AXISOR Limited Warranty.

- Transitions are required only if installing AXISCOR in a room or area that is larger than 100 lineal ft. in any direction.

- Irregularities in concrete subfloor should be filled and leveled using a cementious patching or leveling compound (Follow Subfloor Flatness Tolerances).

- Installing on Stairs or vertical surfaces such as walls will void your Warranty

- When installation over existing ceramic tile floors it is not necessary to fill grout lines (Follow Subfloor Flatness Tolerances).

- Any glue down installation will void the Warranty

- Subfloor RH/MVER Recommendations 85% Relative Humidity/ 8 lbs. MVER (Moisture Vapor Emission Rating) Radiant Heat Approved

- AXISCOR flooring is recommended in enclosed 3 season rooms that meet the approved subfloor requirements

- Allow for a 1/4” expansion gap around perimeters walls & heavy fixed objects such as cabinetry, pipes, or baths.

- “Waterproof” - Structural integrity of AXISCOR flooring will not degrade due to contact with moisture/water.

PRE-INSTALLATION BASICS

If AXISCOR is subject to extreme hot or cold temperatures prior to installation, allow the product to acclimate 48 hours or to room temperature(between 55° - 85°F - 13°- 29°C or average temp. of 70 degrees (21.1°C)

Post installation Environmental Conditions should be maintained at -20 ̊F (-29°C) - 140 ̊F (60°C)

Product should be stored (flat) in a dry area away from direct sunlight. Do not leave next to heating or cooling ducts. All work involving water must be completed well in advance of the installation of AXISCOR. Do not store flooring in uncontrolled environmental conditions. For example, garages and exterior patios are not acceptable areas to store flooring. Flooring stored on a concrete slab should be elevated at least 4" to allow air circulation under cartons. Ensure that all trades have been completed, including; drywall, plasterwork, plumbing, painting, etc.

Shade Variations: Randomly pull planks from three or more different cartons to ensure good color and shade mixture. Carefully inspect each plank for visual defects prior to installation. Do not install damaged planks.

JOB SITE EVALUATION

Prior to installation, the homeowner or installer must ensure that job site conditions (including subfloor/substrate, ambient temperature and relative humidity) will not negatively affect the floor. The manufacturer is not responsible for damages associated with improper installation or poor site conditions.

Moisture

Test all concrete subfloors for moisture content and document the results. Visual checks are not reliable. Moisture must still be checked even though AXISCOR vinyl plank flooring is waterproof in order to protect surrounding structure.

Crawl Spaces

Concrete slab or ground must be dry. Ensure that crawl spaces have open vents year-round to ensure proper air circulation and prevent moisture build-up. The ground in the crawl spaces must be completely covered using 6 mil polyethylene. Crawl space clearance between the earth and underside of joists should be no less than 18" and the perimeter vent area should be equal to 1.5% of the total square footage of the crawl space or as mandated by code.

APPROVED SUBFLOORS

Concrete, Plywood, OSB, Particleboard, Chipboard, Hardwood (Solid, Engineered, Parquet), Tile (Ceramic, Terrazzo, Stone, Asbestos, Peel and Stick), Fully Adhered Non-Cushion Sheet Vinyl, Metal, VCT.

All subfloor requirements noted below must be met prior to the installation of AXISCOR vinyl plank flooring.

GENERAL REQUIREMENTS (ALL SUBFLOORS)

- Must be flat to within 3/16" in a 10ft. span; no bumps or low spots. Subfloors should not slope more than 1" per 6ft.

- Must be clean: no construction debris, soil, mud or any other objects on or adhering to the floor; if necessary, scrape and sweep away before the installation; no protrusions of nails, debris, or metals should remain.

- Must be free from moisture-related conditions that can damage the installed flooring.

- Be structurally sound without deflection.

CONCRETE SUBFLOORS

- High spots can be removed by grinding; depressions can be filled with patching compound formulated for use in floor installation.

- Cure for at least 90 days (applies to newly-laid concrete slabs).

- Can be either sealed or unsealed.

- Between 7 and 9 alkalinity when performing pH test (ASTM F710).

- Moisture content should meet one of the following criteria:

- 4% max. when tested using Tramex Concrete Moisture Encounter.

- Less than 8 pounds per 1000 sq. ft. per 24 hours MVER (Moisture Vapor Emission Rating) when using Calcium Chloride test (ASTM F1869).

- 85% max. when performing Relative Humidity Testing (ASTM F2170).

WOOD (PLYWOOD, OSB, PARTICLEBOARD, CHIPBOARD, SOLID HARDWOOD, LUAN) SUBFLOORS

- Wood subfloors must be A.P.A approved with a minimum grade of “BB” or “CC”. For reference, A.P.A. is the acronym for an organization originally known as the “American Plywood Association”, and that is now known as “The Engineered Wood Association”.

- Perform moisture tests using a reliable moisture meter in multiple locations. Moisture readings should never exceed 14% for plywood, OSB, particleboard, chipboard, and solid hardwood subfloors. If moisture readings exceed 14%, it should be corrected at the job site before installing AXISCOR vinyl plank flooring.

TILE, TERRAZZO, ASBESTOS TILE, RESILIENT TILE, NON- CUSHION SHEET VINYL, AND METAL SUBFLOORS

- Existing floors must be firmly attached to the structural floor.

- Fill in grout lines larger than ¼" on ceramic tiles, terrazzo, quarry tiles, and similar floors with a cementitious leveling and patching compound.

- Install over one layer of vinyl only.

IN-FLOOR RADIANT HEAT

This product can be installed over radiant heat concrete subfloors. Consult with the radiant heat system manufacturer to ensure that the system is compatible with vinyl flooring.

- Electric and hydro systems are acceptable.

- In-floor radiant components must be a minimum of ½" below flooring.

- Floor surface temperature should never exceed 85°F.

- Heating system should be operational for at least two weeks prior to installation to calibrate temperature settings.

- Flooring cannot be laid directly over radiant heating mats.

NON-APPROVED SUBFLOORS

- Carpeting/Carpet Pad

- Laminate

- Perimeter Bonded or Cushioned-Back Vinyl Flooring

- Cushioned Vinyl Flooring

- Sleeper Substrates

- Floating Floors

- Rubber

Remove the floors noted and remove old adhesive before installing AXISCOR Rigid Core flooring.

CAUTION: If you contemplate the removal of a resilient floor covering structure that contains (or is presumed to contain) asbestos or lead, you must review and comply with all applicable regulations. Do not sand, dry sweep, dry scrape, drill, saw, bead blast, or mechanically chip or pulverize existing resilient flooring, backing, lining felt, asphalt “cut- back” adhesive, or other adhesive. These products may contain asbestos fibers and/or crystalline silica. Avoid creating dust. Inhalation of such dust is a cancer and respiratory tract hazard. Smoking by individuals exposed to asbestos fibers greatly increases the risk of bodily harm. Unless positively certain that the product is a non-asbestos containing material, you must presume it contains asbestos. See “Recommended Work Practices for Removal of Resilient Floor Coverings” (rfci.com) for detailed information and instructions on removing all resilient covering structures.

HELPFUL POINTERS & PREPARING FOR INSTALLATION

- Work area should be well lit. Proper visibility ensures that color is consistent and that visually defective planks are detected and removed. Subfloor must be clean and free of debris.

- Undercut doorjambs and casings using a handsaw laid flat on a piece of scrap flooring. Never undercut metal door casing.

- Carefully remove the existing base, shoe molding or thresholds. They can be reused to cover the ¼" expansion gap around the edge of the room.

- The minimum length of the first and last plank is 8". If the last plank will be less than 8", adjust the length of the first plank. The remainder of the last plank can be used as a starter plank on the following rows.

- The minimum end-joint stagger is 8". Keeping this in mind, vary the distances from end joints row-to-row for a more random and realistic installation.

- Shade Variations: Randomly pull planks from three or more different cartons to ensure good color and shade mixture. Carefully inspect each plank for visual defects prior to installation. Do not install damaged planks.

AVAILABLE MOLDINGS

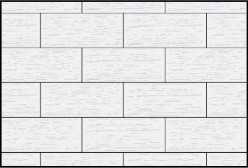

NOTE: AXIS PRO 12 Tiles ONLY must be installed in a brick pattern, where the seams are staggered.

*Brick pattern is for tiles only – not planks

INSTALLATION

INSTALLING FIRST ROW

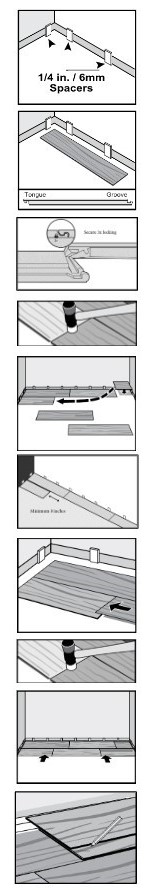

- Set spacers to allow a minimum gap of ¼" around the perimeter of the subfloor for movement or product expansion. Do not remove the spacers until the installation is complete. The expansion gaps should be covered by molding.

- Measure the length of the room in inches. Divide it by the width of the planks that are to be installed. If the resulting number is less than the to be installed plank width, you will need to cut your first-row planks accordingly to avoid having planks that are less than the plank width on the opposite end of the room.

- Note: To cut a plank, simply measure and mark the plank. Then, use a straight edge and utility knife to score and snap. You will also need to back-cut the under pad on the bottom of the plank. If you have difficulty using this method, you can use a jig saw, circular saw or miter saw. (60 or 80 tooth saw blade)

- Installation should start in a left-hand corner and proceed from the wall with the tongue facing the wall. Position the first plank 6" from the starting wall but not up against the spacers. The entire row will be moved against the spacers in a later step.

- The end joints of the planks in the first row are assembled by sliding planks together and gently dropping the short side of the plank into the short side of the adjoining plank. To secure the joint, press down with your thumbs on both ends of the short sides and continue pressing until the two planks are flush along the end joints. It is important to ensure that the plank ends are perfectly aligned, smooth, and level. Use a soft-faced rubber mallet to tap the end joint starting from the outside.

Cut the last piece of the row to fit and allow for the ¼" expansion gap (if you have not already done so). Install as shown.

INSTALLING SECOND & REMAINING ROWS

- Cut the first plank of the second row to two-thirds its length or make sure there will be at least an 8" stagger between end joints. Angle the long tongue edge of the plank into the long groove edge of the first plank. Drop and lock the end joints together. Make sure there are no gaps, do not tap the short end into place if the long joint is not properly engaged, as doing so can cause damage to the tongue and groove

- Note: When starting a new row, you can use the cut piece from the previous row, as long as it is more than 8" and the stagger between seams still is greater than 8".

- Attach the second plank by connecting the long side to the first row and sliding it up to the short end of the first plank. Check that the long joints of the planks are properly engaged and then press the short joint into place with your fingers.

- Lightly tap down on top of the plank at the short joint with the soft-faced rubber hammer. Continue installing the remainder of the row in this fashion.

- After installing the last piece of the second row, slide the entire assembly against the spacers on the starting wall, maintaining the required ¼" expansion gap.

- Install remaining rows, one row after the other, and maintain the required 8" stagger throughout the install. Tap and square each plank as in step 3.

INSTALLING THE LAST ROW

- Most often the entire length of the last row will need to be cut so that it is narrow enough to fit the remaining space. Cut the first plank of the last row to length (if necessary to follow stagger pattern). Place directly on top of the previously installed row. Then, take another plank and place it against the wall on top of the plank to be cut for width. Mark the plank (lengthwise), cut to size. Remember to allow for the ¼" expansion gap against fixed objects.

Install the plank with the cut side always facing the wall. Continue to cut and install remainder of the planks in the last row.

Note: Be sure to leave a minimum of ¼" expansion space around all fixed objects, cabinetry, and metal door jambs.

IMPORTANT: If you notice both planks are not at the same height or not locked together properly, follow the dissembling instructions at the bottom of the page, dissemble and check if any debris stuck in the lock is obstructing. Failure to properly line up the end joint and attempting to force it in while out of alignment could result in permanent damage to the end joint.

AFTER THE INSTALLATION

Remove spacers. Cover expansion spaces with quarter round or other trim.

Fill any expansion spaces around potentially wet areas (such as refrigerators, tubs, etc.) with premium, waterproof 100% silicone caulk.

Remember, the use of coordinating T-Molds is required when installing AXISCOR in a room or area that is larger than 100 lineal feet in any direction, so that the floor is separated into sections that are no larger than 100ft. x 100ft. per section.

Save and protect any leftover planks. Do not discard, they can be used for replacement in the event you need to replace a plank in the future.

CARE & MAINTENANCE

DAILY MAINTENANCE

- Vacuum your floors instead of sweeping

- Vacuum your floors as part of a regular weekly routine, as well as after any event that has left dirt behind. Gravel and dirt of any kind have the potential to damage the floor if not removed properly and promptly. Vacuuming, with a floor attachment rather than a beater bar, is preferred to sweeping because it not only addresses the surface of the floor but pulls particulates from between the planks.

- Never use a rotating brush, floor scrubbers, jet mops, buffers or similar products.

- To minimize the amount of dirt and grime on your floors, place mats outside and inside of all exterior doors.

- The occasional spill should be cleaned up immediately with a dry cloth. A damp cloth may be used for a stickier mess, but the area should be dried afterwards.

- For lightly soiled areas, clean with distilled water.

- When the cleaning cloth/mop becomes soiled, rinse with clear water and air dry or replace it with a clean one. Following up with a clean, dry cloth will remove residual streak-marks and spots.

- Promptly remove any standing water, pet urine or other liquids.

- If using a store-bought off-the-shelf floor care product, follow manufactures guidelines. Test the product in an inconspicuous place (e.g. closet, corner, or scrap pieces) for potential, adverse side effects.

DO NOT

- use a steam cleaner.

- vacuum with a beater bar or power rotary brush head.

- use any cleaning agents containing wax, oil or polish. Leftover residue will form a dull film.

- use steel wool or scouring pad, as they will scratch the floor.

- use any dust cleaners, as they may cause your floor to become slick or damage the finish.

PREVENTATIVE MAINTENANCE

- Protect your floor when using a dolly to move furniture or appliances. Protective sheets and/or plywood may be needed. Never slide or roll heavy furniture or appliances across the floor.

- Use flat floor protectors (felt) on all furniture legs. Periodically clean protectors to remove grit that may become embedded and cause scratching.

- Minimize abrasive material and dirt by placing mats on both sides of exterior doors and by using area rugs in high-traffic areas.

- Use NON-RUBBER backed mats that are labeled “colorfast” by the manufacturer. Non-staining, vinyl-backed mats or woven rugs should be used at all entrances to prevent dirt and grit from being tracked onto your floor.

- Use protective mats beneath rolling chairs and keep furniture casters clean. We recommend the use of a hard surface (non-studded), non-rubber chair mat to protect your floor from office chairs with casters. Light, rolling furniture should be outfitted with broad-surface, non-staining barrel-type casters that have been engineered for hard surface floors. Such barrel-type casters should be a minimum of 1" wide and at least 2" in diameter.

- Spike or stiletto heels can cause damage to your floor.

- Also remember to keep your pet's nails trimmed or filed.

For questions and concerns: info@axiscor.com

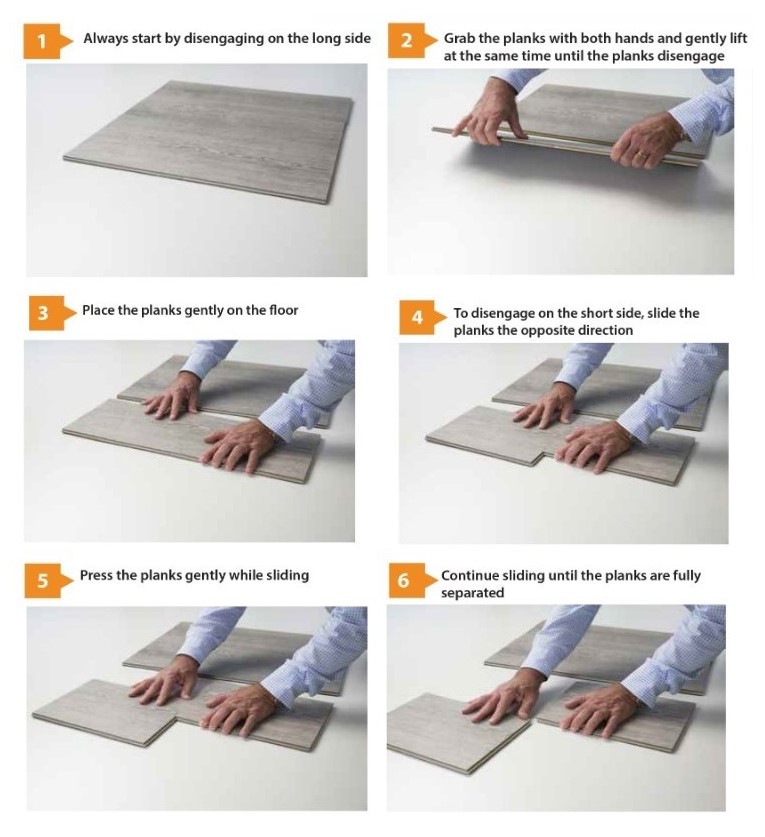

How to Engage